KEY TAKEAWAYS

- Post frame is a structural system that uses vertical posts, engineered trusses, purlins, and girts to create versatile buildings suited to a variety of rural uses.

- Design choices drive long-term value when size, doors, layouts, and finishes match how you plan to use the building every day.

- For rural applications, post frame construction can be a cost-efficient alternative to traditional construction methods, without sacrificing quality or practicality.

- Regional detailing protects performance as snow, wind, and moisture vary across regions and demand proper engineering and thoughtful design.

- Post frame buildings are popular in rural Canadian settings because they offer a unique combination of strength, versatility, efficiency, and design customization.

You want a building that works hard to make daily routines smoother and work more productive, without worrying about durability and longevity. Post frame construction gives you open space, tall access points, and strength that stands up to Canadian seasons. The structure uses fewer foundation points than many systems and still delivers a solid, long‑lasting structure. You get room to move, room to store, and room to grow.

Rural property owners choose post frame for practical reasons. Clear spans keep interiors open for maneuvering equipment, and shop layouts remain flexible. Equipment doors can be wide and tall without complicated interior columns, while versatile designs tailor the building to your unique needs. The method adapts to farms, acreages, equestrian facilities, commercial sites, and residential projects that need a dependable structure.

What is a Post Frame Building?

A post frame building is a structural system built on widely spaced vertical posts that carry roof and wall loads directly into the ground. Engineered trusses span between those posts to create clear interiors without load-bearing walls, giving owners tall, open space that fits equipment, livestock, or workshop layouts. Horizontal members called purlins and girts support the roof and wall cladding, and trims finish the building to seal and protect the envelope.

Post frame buildings do not rely on a continuous concrete foundation like more traditional buildings. Instead, the structure transfers loads to the ground through the individual posts, reducing excavation requirements and eliminating the need for a full concrete foundation. Rather, the term ‘foundation’ in post frame construction refers to how the posts are set below grade. Instead of a single standardized approach, builders offer different post frame foundation options based on soil conditions, longevity goals, and budget. In some applications, wood posts are set directly into the ground, with pressure-treated material used anywhere the post contacts soil. Other systems add protective sleeves or barriers at ground level to improve moisture protection over time. Another option keeps wood entirely out of the ground by using buried piers made from concrete, steel, or other durable materials, with the wood posts attached above grade. Each approach is selected to match site conditions, expected service life, and overall project budget.

How Post Frame Construction Works Step by Step

A predictable, smooth process keeps decisions simple and progress steady. Clarity at each stage helps you understand what is happening on your land and why it matters. The sequence below reflects how a strong building comes together with minimal surprises. Good planning reduces rework and protects timelines.

- Property visit & goals: Walk the site with a post frame builder to confirm access and setbacks, and align on size, height, and layout needs

- Preliminary design: Lock in dimensions, door placements, colours, and any other features that add value to your building

- Engineering & permits: Produce sealed drawings for local snow and wind values, then submit for approvals

- Manufacturing & staging: Fabricate laminated posts and trusses, stage purlins, girts, cladding, and trims for delivery

- Squaring & drilling: Construction crews square in the building before drilling holes for the posts

- Framing & enclosure: Stand posts and install trusses, fasten purlins and girts, add building wrap, metal cladding, man doors, windows and trims

- Finish details: Install soffit & fascia, wainscoting, eavestroughs & downspouts and other finish details

- Interior finishing: Insulate and install interior wall and ceiling metal cladding to create bright, durable interior surfaces for workshops or barns

- Building walkthrough: Builders tidy the construction site and complete a thorough walkthrough of the building to check that quality and craftsmanship meet your expectations

Clear communication and planning keep everyone aligned as materials arrive and crews work through milestones so property owners experience a smooth, stress-free process. The building closes in quickly once framing is complete, which protects the structure from weather. A final walkthrough reviews door operation, building seal, and basic care.

“A post frame building is a strong, adaptable structure engineered to fit your land, your work, and your style.”

Why Post Frame Buildings Are a Popular Choice in Canada

Rural property owners across Canada want space that is simple to use, strong through snow and wind, and designed with their needs in mind. Post frame offers that through clear spans, durable materials, and proven engineering. The system suits machine sheds, agricultural workshops, calving barns, hay storage, indoor riding arenas, hobby shops, garages, warehouses, and aircraft hangars. Design choices keep the look clean while protecting the structure for the long haul.

Engineered for Structural Strength

Rural Canadian building sites experience heavy snow loads, gusting winds, and shifting seasonal conditions, all of which place significant demands on a structure. Post frame buildings are engineered to meet those forces head-on through deliberate design. Rather than relying on extreme rigidity, post frame construction is intentionally designed to allow controlled movement within the structure. This ability to flex slightly under load helps the building absorb wind, snow, and seasonal ground movement, then return to position—reducing stress on materials and lowering the risk of long-term damage.

Engineered trusses carry roof loads efficiently across long spans, while deep-set posts anchor the building and resist uplift and lateral forces in high-wind environments. Horizontal purlins and wall girts create a continuous fastening surface that ties the exterior cladding back into the frame, helping distribute loads evenly throughout the structure. Together, these components form a strong, resilient system that performs reliably in Canadian climates. The result is a building that lets you rest easy knowing it will stand strong.

Clear Span Space That Fits Work & Animals

Open interiors are a signature of post frame. With exterior posts bearing the full weight of the structure, you can back implements straight in, pull a grain cart through, or set up a large indoor arena without being limited by interior load-bearing walls. That same clarity helps with horse stalls, maternity pens, and alleys, when animals need space and safe movement. A 40’ x 60’ x 16’ workshop footprint, for example, feels much larger and functional when the interior is free of load‑bearing walls.

Flexibility also shows up in daily tasks. Wash bays, tool storage, and tack rooms can be added as non‑structural partitions. Mezzanines make use of height for storage without interfering with floor space. Rural property owners get endless layout possibilities and room to work in a post frame structure.

Cost Efficient Alternative to Traditional Construction

Post frame buildings are a cost-effective alternative to traditional construction because they’re engineered to deliver strength with fewer structural materials. Wide post spacing reduces the amount of lumber required, and engineered trusses span long distances without relying on interior load-bearing walls. Key components such as trusses and laminated posts are manufactured in advance for fast, efficient installation. That simplicity lowers material cost and keeps labour hours predictable. Post frame building owners also save on foundation work, as sturdy posts set directly in the ground remove the need for extensive excavation and a full concrete foundation.

Those savings continue long after the building is complete. Durable metal cladding keeps maintenance light, preserves its appearance, and resists hail, wind, and everyday wear. By reducing labour, material expenses, and long-term upkeep, post frame structures remain economical compared to other building methods. The result is a building that stands strong, supports a wide range of rural uses, and offers lasting value without compromising the quality or performance your property demands.

Energy Efficiency

Post frame construction naturally limits thermal bridging because structural posts are spaced widely compared to stick frame walls. That spacing creates wider, deeper cavities that accept more insulation with less interruption. Property owners who heat and cool their shops, barns, or riding arenas appreciate interiors that hold temperature more predictably. Clear span layouts also support efficient air movement, making heating or cooling easier to manage.

The envelope can be refined through insulation, building wrap, soffit intake, and thoughtful sealing. These details work together to stabilize indoor conditions. Daylight from wall lights or door windows further reduces electrical use during the day. Efficiency becomes a practical outcome of post frame rather than a complicated, costly upgrade.

Low Maintenance Durability

Metal cladding offers low maintenance care compared to vinyl siding and shingles. It withstands hail and wind well and keeps its appearance with simple wash downs. Trim details and building wrap support moisture control and protect the envelope over time. Post frame building owners spend less time repairing exterior surfaces and more time using the building.

The structural system also contributes to long service life. Widely spaced structural posts create a strong yet flexible framework that performs well under snow and wind loads. Combined with durable materials and thoughtful detailing, this flexibility helps reduce long-term stress on the building and supports decades of reliable use.

Tall Equipment Doors and Vertical Clearance

Post frame buildings are well suited to taller wall heights because posts and engineered trusses handle vertical loads cleanly. That strength allows for overhead, sliding, or bi fold doors that fit large machinery, RVs, horse trailers, or even small aircraft. Workshops and garages often need generous height so vehicles can be lifted, maintained, or stored safely. The system accommodates larger doors without additional engineering and framing.

Clear vertical space improves workflow. Tall ceilings allow mezzanines without crowding floor activities. Farm buildings, acreage workshops, and commercial buildings all benefit from vertical storage by gaining more usable space without expanding the footprint.

Fast Construction Sequence

Post frame construction uses fewer structural components than many conventional systems, and key parts such as laminated posts and trusses are manufactured off-site for consistency and fast installation. Without a continuous concrete foundation, site preparation is simpler and construction begins sooner. Crews can stand posts and trusses quickly and enclose the building early in the sequence. That efficiency helps you start using the structure sooner.

Rural property owners keep choosing post frame buildings because they deliver a rare combination of structural strength, cost efficiency, and adaptability that aligns with how work gets done on their land. The system stands up to harsh Canadian weather, supports clear span interiors for vehicles, equipment and livestock. Over time, the low-maintenance exterior and durable structural components make ownership predictable and economical.

Benefits of Choosing a Post Frame Building for Your Property

Post frame’s strutcural advantages—fast construction, clear-span interiors, efficient envelopes, and durable materials—translate into tangible benefits for your property. These fundamentals create spaces that are easier and more comfortable to work in, more economical to operate, and better align with the demands of rural life. The points below show how the advantages of post frame become practical value on your property.

- Smooth workflow & routines: Design flexibility drives operational efficiency in a post frame building. With no interior load-bearing walls, the layout can be tailored precisely to how you live and work—hay storage placed to streamline feeding, tool and parts areas for intuitive access, or large equipment doors aligned with your fleet and daily movement patterns.

- Improved organization & usability: Tall building heights and vertical room create opportunities to add full or partial second-floor functionality to better organize your space, plus add offices or living areas to get more from the building. The result is a building that feels more organized, orderly, and increases productivity.

- Lower cost over the building’s life: Wider wall cavities for insulation, fewer themal bridges, and durable materials translate directly to lower heating, cooling, and maintenance costs. The structure’s simplicity reduces energy loss and keeps the building envelope efficient throughout seasons. Building owners benefit from controlled operating costs and predictable maintenance requirements.

- Better indoor comfort: Enhanced insulation capacity in post frame buildings promote stable indoor temperatures while large, open interiors make it easier to manage ventilation and airflow, which is especially important for workshops and livestock facilities.

- Style that fits your eye: A wide range of layout possibilities and features create a clear route to customize your building to your aesthetic taste and preferences. Metal colours, wainscoting, stone accents, porches and rooflines can be personalized to create endless design combinations. Rural property owners gain a building that feels like it fits on their land.

- Smooth, enjoyable construction process: Fast construction is a natural outcome of the post frame system’s engineered simplicity. With fewer foundation requirements and pre-manufactured components, crews can stand the structure and close it in quickly. That predictability limits delays and allows owners to start using the building sooner.

Strong benefits come from a combination of the post frame systems and clear design intent. When structure, workflow, protection, and design options come together, post frame construction provides a building that serves your land for years.

Structural Features That Define Post Frame Construction

Post frame construction is defined by a structural system that relies on a few core components working in unison. Vertical laminated posts carry roof and wall loads to the ground or to concrete piers. Engineered trusses span between those posts to create clear interiors without the need for interior load-bearing walls. Purlins and girts provide the horizontal framework that supports metal roof and wall cladding, completing a strong and durable building. These key elements appear in every post frame building because they form the basis of the system’s strength and longevity.

Everything beyond these essentials becomes a matter of personalization rather than structure. You choose features based on use, such as tall equipment doors for farm machinery, ventilation for barns or workshops, or interior metal cladding for bright, cleanable surfaces. Those features support workflow, appearance, comfort, or animal welfare, but they do not define post frame construction itself.

Core Structural Features of Post Frame Construction

| Feature | What it is | Why it matters for owners |

| Laminated posts | Vertical structural members that carry roof and wall loads | Strong, durable primary structure with capacity for tall walls and wide openings |

| Engineered trusses | Roof components spanning between posts | Clear span interiors sized for local snow loads and intended building width |

| Purlins & girts | Horizontal framing members connect posts and trusses | Stiffness, fastening surfaces, and proper load transfer across the structure |

| Metal cladding | Exterior steel panels for roof and walls | Durable protection, weather resistance, and a clean, low-maintenance envelope |

Once the main structure is built with these key components, optional features such as overhead, sliding, or bi fold doors, wall lights, soffit and fascia, interior metal cladding, and porches are added according to your priorities and building use. Regardless of additional features, the components of the main building system stay consistent: a strong frame, a dependable foundation, and a protective metal shell built for Canadian conditions.

Factors That Impact the Cost of a Post Frame Building in Canada

Costs follow design choices and project-specific factors. Size, height, and design complexity influence material costs and labour hours. Site access, slope, and topography of the build site shape pre-construction costs for dirt work and site prep. Regional building codes also play a key role and influence engineering requirements.

- Footprint & height: Larger spans and taller walls increase material and labour requirements

- Equipment doors & man doors: Quantity, type, and size influence structure, hardware, and trims

- Snow, wind & exposure: Regional code values and exposure categories drive engineering and fastening schedules

- Site preparation & access: Grading or dirt work to level the building area, trenching to tie into utilities, and distance from suppliers influence preparation time and pre-construction tasks

- Design complexity: More complex layouts and detailed finishes can add man-hours and material costs

Clarity on use will help you select features that provide the most value to your daily life while aligning with your budget. Good drawings reduce changes and keep approvals efficient. Post frame buyers stay in control and feel confident when each cost driver ties back to their unique uses.

Regional Considerations for Post Frame Buildings Across Western Canada

Western Canada covers many climates and exposures. Remuda’s work through British Columbia, Alberta, and Saskatchewan has given us insight into snow loads, wind exposure, and moisture levels that vary by region and even by site. Engineering and detailing should match those realities. A building that fits your location will feel dependable year after year.

- Prairie wind exposure: High winds and drifting call for bracing attention and careful door seals

- Foothills snow & freeze-thaw: Variable snow loads require truss design tuned to snow loads and water management that protects posts and slabs from movement

- Northern cold: Insulated envelopes, vestibules at man doors, and ventilation planning protect comfort and materials

- Urban‑adjacent acreages: Setbacks, sightlines, and finishes guide colour and trim choices, and some subdivisions require outbuildings to match the primary residence to meet community standards.

Localized engineering and practical details that consider the specifics of your building site protect your investment. Thoughtful designs are the difference between seasonal headaches and steady year-round performance.

“Rural property owners care about how a building feels to use, how it holds up, and the value it adds to daily routines.”

Comparing Post Frame Buildings to Other Construction Options

The main differences between post frame, stick‑built, and steel frame construction are materials, how loads travel to the ground and how well that structure enables wide, unobstructed space. Post frame uses widely spaced posts with engineered trusses to create clear spans over a minimal foundation, while stick‑built uses many closely spaced studs and beams on continuous foundations, and steel frame uses steel columns and rigid frames on engineered piers. Those choices affect interior flexibility, door sizing, site work, and building costs. Matching the system to your use and site conditions protects performance and lifespan.

Post frame shines for rural sites, tall equipment doors, and simple expansions. Stick‑built can align with smaller footprints or heavy interior partitioning as part of the structure. Steel frame can reach very long spans or satisfy industrial specifications when that scale is required.

| Criterion | Post frame | Stick‑built | Steel frame |

| Primary structure | Laminated posts with engineered trusses | Stud walls with beams and rafters | Steel columns with rigid frames |

| Foundation | Posts in ground or on concrete piers | Continuous concrete foundations | Engineered piers and anchors |

| Clear span capability | Spans greater than 80’ are common | Moderate, interior beams or columns commonly restrict layouts | Strong for very long spans |

| Equipment door compatibility | Excellent for large overhead, sliding, or bi‑fold doors | Good for standard overhead door sizes | Excellent, often integrated into frames |

| Interior flexibility | High, partitions are non‑structural | Lower, many walls are structural | High, with secondary framing for finishes |

| Site impact | Dirt work to level the building pad only, no excavation required | More continuous excavation and formwork | Heavy coordination and crane access |

What Are Common Applications of Post Frame Buildings?

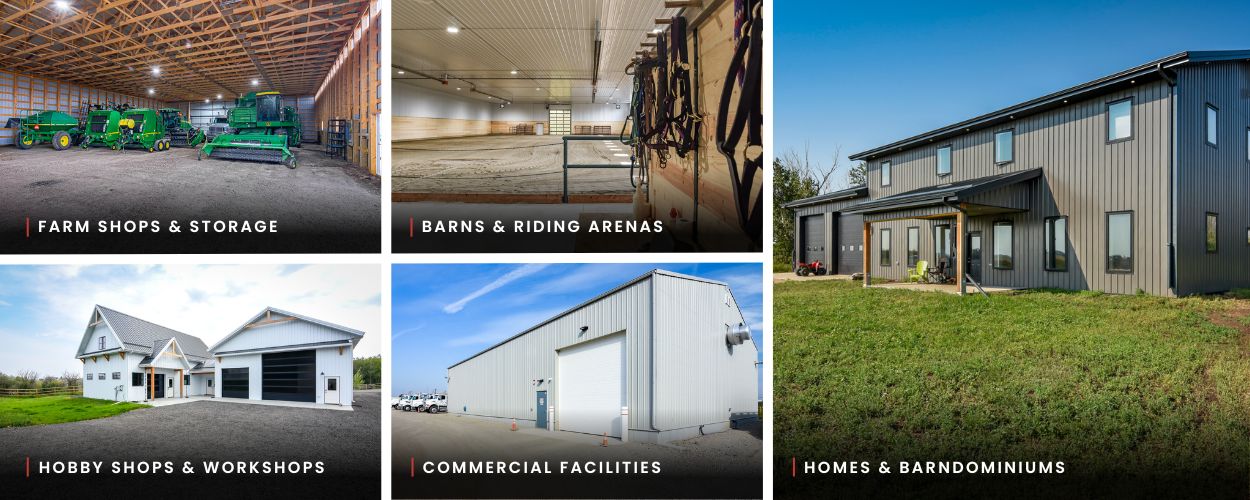

Post frame buildings have deep roots in the agricultural world, having been used as barns or storage buildings on farms for over a century. Today, however, post frame construction is a popular choice for rural buildings of all types and are commonly used for:

- Agricultural buildings: Farm shops, machine sheds, calving barns, and hay storage

- Acreage buildings: Garages, workshops, and hobby shops

- Equestrian buildings: Riding arenas and horse barns

- Commercial buildings: Offices, warehouses, retail spaces, and workshops

- Residential buildings: Barndominiums (shop homes) and bungalows

How Remuda Supports You With the Right Post Frame Building

With Remuda, you get a personal, high‑touch process that starts on your property. We can walk the site with you to confirm access, setbacks, drainage, and prevailing wind, then talk through size, height, and other design options that match how you plan to use the space. Our team manufactures laminated posts and trusses in‑house, which keeps quality and scheduling in our hands from day one. Drawings are engineered for local snow and wind, then coordinated with permitting to keep the build organized. The promise is simple: Above & Beyond Ordinary from start to finish.

A thoughtful building design fit to your needs and use case ensures long-term value, and we help you choose features that make the most sense. Arenas often get kick walls and wall lights, while hobby shops lean on insulation, interior metal cladding, and thoughtful window placement. Farm operators focus on tall equipment doors, clear lanes, and storage height, and rural business owners may add exhaust fans and mezzanines for storage. For residential buildings and barndominiums, we provide the structural shell to lock‑up, ready for licensed trades to complete interiors according to your plan. Talk to a Building Consultant when you are ready to turn ideas into a strong, clear plan tailored to your needs and vision.

FAQs About Starting Your Post Frame Project

A post frame building uses vertical structural posts, engineered roof trusses, purlins, and girts to create a wide, open interior with minimal need for interior load-bearing walls. The vertical posts are set securely in the ground or on engineered piers, and each post pair supports the weight of a single truss to form the primary structural system. Horizontal purlins and wall girts tie the frame together and provide fastening surfaces for the cladding. Once metal panels are installed on the roof and walls, the structure encloses efficiently, creating a clear span building that is strong, adaptable, and well-suited to rural and commercial applications.

Post frame construction is the step‑by‑step process of designing, engineering, and assembling a post frame system on your site. It starts with a property visit and drawings sized for local snow and wind, then moves through manufacturing of key building components, sourcing materials, then framing, enclosure, and finishing details. The outcome is a strong, usable space with open interiors.

A post frame home uses the same structural approach to create a residential building with open interiors and advantages that are well-suited to life in the country. The frame supports large openings and flexible layouts that can be finished to suit personal tastes and preferences. Exterior details like windows, porches, wainscoting, and colour combinations set the look while insulation and ventilation support comfort and energy efficiency. Families value the convenience, security, and flexibility of barndominiums that align with their needs while living in the country.

A post frame barn covers animal housing, plus tack and hay storage. Clear spans help with alleys and pen layouts, or accommodating a wash bay. Post frame barns may include kick walls, exhaust fans, and windows to improve safety and ventilation for both livestock and owners.

Post & beam and post frame are different systems with different goals. Post & beam uses heavy timbers and traditional joinery to create a structure and an exposed look. Post frame uses laminated posts, engineered trusses, and metal cladding to build wide, functional interiors quickly and efficiently. The best choice depends on use, style goals, and how you plan to use the space day to day.

Yes and no. The terms are often used interchangeably, but they are not exactly the same. In both building types, the structural system is fundamentally the same. The primary load-bearing framework is made up of embedded vertical members, roof trusses, and horizontal purlins and girts that transfer loads efficiently to the ground while creating large, clear-span interiors.

The key distinction lies in the vertical supports themselves. Traditional pole buildings relied on round poles, like telephone poles. Modern post frame buildings use engineered, pressure-treated laminated posts designed for uniform strength, improved durability, and predictable long-term performance. This evolution is what separates outdated pole building methods from today’s post frame construction standards.